Thermal mass flow technology provides superior custody transfer meter measurements for:

Thermal mass flow meters provide input to energy management software to get an accurate overview of energy usage across facilities, buildings, or equipment. The meters will help you meet environmental requirements and prove compliance.

Thermal mass flow meters provide flow measurement data to help building managers of university campuses and industrial parks detect and stop leaks, improve energy efficiency, and track energy usage among equipment and facilities.

In Oil & Gas production, thermal mass flow meters are ideal for ensuring accurate consumption cost allocation in spite of variations in natural gas temperature, pressure, and flow rate.

The Oil & Gas industry uses allocation as a part of the hydrocarbon accounting process to calculate royalties. The flow of petroleum from contributing sources—like natural gas—must be measured or "allocated" by a custody transfer oil and gas meter to determine ownership of sources that become commingled from the source to storage or the point of sale.

Investors in oil and gas exploration or production often share costs over multiple owners to decrease individual risk. However, once production begins, determining ownership percentages from the product can become tricky if there are inaccuracies in the calculation of flow.

Beyond ownership of produced hydrocarbons, the objectives of allocation are:

An energy accounting system creates accurate data on flow, maintaining the integrity of these objectives according to industry standards.

Daily accounting of natural gas usage is a priority for a variety of industrial facilities with multiple processes and/or commercial facilities, such as apartments or university campuses that need to track usage across these processes or buildings.

Fuel gas flow meters are used as sub-meters in these cases to analyze demand, improve operating efficiency, reduce waste, and adjust for peak usage.

In the past, flow meter types such as orifice plates, venturis, vortex, and custody transfer turbine flow meters were used to measure natural gas consumption.

However, these volumetric devices offer limited rangeability and require pressure and temperature transmitters to compensate for density changes. In addition, these designs contain moving parts that require periodic maintenance, adding to costs and downtime.

Today, the thermal mass flow meter has become the preferred device for many energy accounting applications. This type of meter measures gas mass flow directly, with no moving parts.

They have no need for additional hardware or pressure or temperature compensation. Thermal mass flow technology also provides better rangeability and a lower pressure drop than volumetric flow meters.

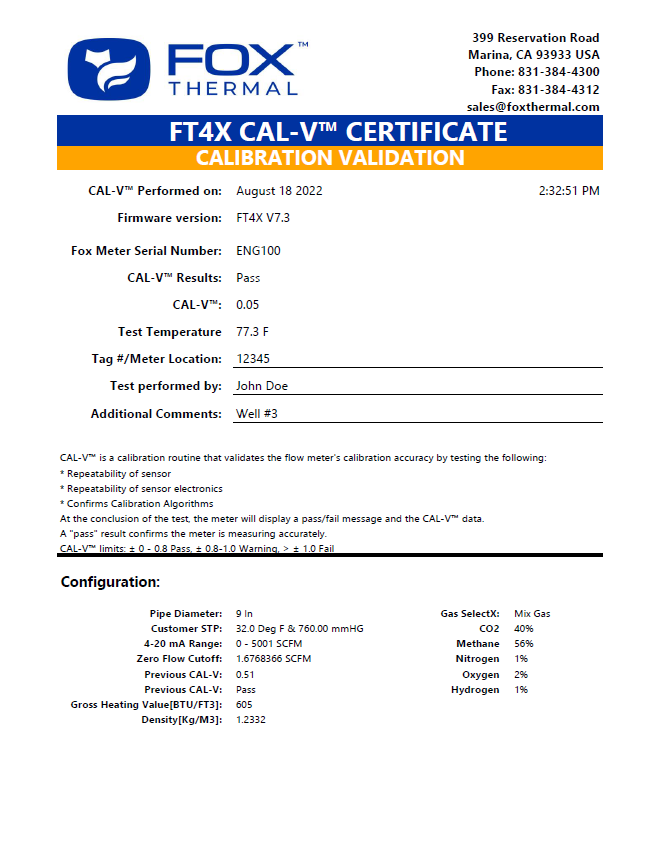

The Fox Thermal CAL-V™ Calibration Validation feature is a built-in diagnostic test that allows the user to verify that the flow meter maintains its NIST-traceable calibration. The test can be performed without removing the meter from the process or stopping the flow. It takes only about 3 minutes to complete the test and provides a pass/fail result that meets industry standards.

If you’re not sure which gas flow meter is right for your application, our Help Me Choose app walks you through a short series of questions to help you choose the ideal meter.

Next, enter your process data and energy tracking requirements into our automated product configurator. Drop-down menus and Help icons will guide you to answer each question.

Save the data you entered into the configurator to create a PDF with a model code and application ID. When you're ready, submit your application to Fox Thermal for a quote.

The Model FT1 thermal flow meter is available with Gas-SelectX® and can be easily reprogrammed in the field with the help of DDC-Sensor™ for calculating accurate gas correlations. It can measure a single gas or a mixture of up to 5 specified gases. Comes with the CAL-V™ Calibration Validation test feature to ensure the meter retains its original NIST calibration.

Available in an extended temperature operating range, the Model FT2A can be calibrated to measure an extensive list of dry pure gases and gas mixes.

The FT3 can operate over higher temperatures and measure a wide range of dry pure gases and gas mixes. Comes with CAL-V™ Calibration Validation and Zero CAL-CHECK®. An optional Data Logger is available.

This versatile gas flow meter is available with CAL-V™ Calibration Validation, DDC-Sensor™, and Gas-SelectX® allowing it to be programmed to measure any combination of gases in the gas mix menu in 0.1% increments to create a custom gas mix.

The Model FT4X features CAL-V™ Calibration Validation, DDC-Sensor™, and Gas-SelectX®. For oil & gas applications affected by BLM 3175 and API 14.10, the FT4X is accuracy compliant. It also comes with a built-in data logger for advanced record-keeping and data retention that maintains a 7-year history.

Find out more about the features and benefits of our range of advanced thermal flow meters and how they can help your energy management.

From sub-metering to emissions monitoring to vent gas monitoring, thermal mass flow metering systems provide accuracy and ease of use.

Here you can download product brochures, application guides, white papers, case studies, and other literature about Fox Thermal gas flow meters for energy accounting.